Why Exposed Aggregate Retarder is Essential for Perfect Finishes

Exposed aggregate retarder is a key ingredient to achieve the natural, textured look we love from our aggregate concrete. But what is this retarder, and why is it necessary? Adding a chemical retarder to the top layer is the finishing touch for any exposed aggregate project.

Safe to use and easy to apply, exposed aggregate retarder is the best way to finish your next textured concrete project! Below, we’re going to explain how exposed aggregate retarders are crucial to creating the perfect decorative concrete finish on your new driveway, patio or pathway. Read on and discover everything you need to know about using this vital part of aggregate surface creation.

What Is Exposed Aggregate Retarder?

An exposed aggregate retarder is a water-based material used to reveal the beautiful stones and gravel in your freshly laid aggregate surface. It is a thick, non-hazardous fluid that often comes in bright colours like fluoro green, purple or blue, making it easy to see and remove when needed.

Using these specialised retarders is a simple and safe way to expose your decorative aggregate surface, as opposed to using dangerous concrete finishes that involve acid etching or forceful abrasive blasting. Achieving a uniform result is quite simple, as the colours will indicate where the retarder needs to be washed away, which will also prevent you from overexposing cleared areas of the aggregate or damaging it from excessive cleaning.

Using an exposed aggregate retarder is the best way to achieve uniform exposure to aggregate materials. Most importantly, this process doesn’t cause any damage to the stones or underlying concrete. It’s also much safer and easier to use than other exposure methods, and doesn’t require any speciality concreting tools and equipments.

If you need exposed aggregate supplies in Melbourne, browse the quality range at Australian Slate-Crete Supplies!

How Exposed Aggregate Retarder Is Used

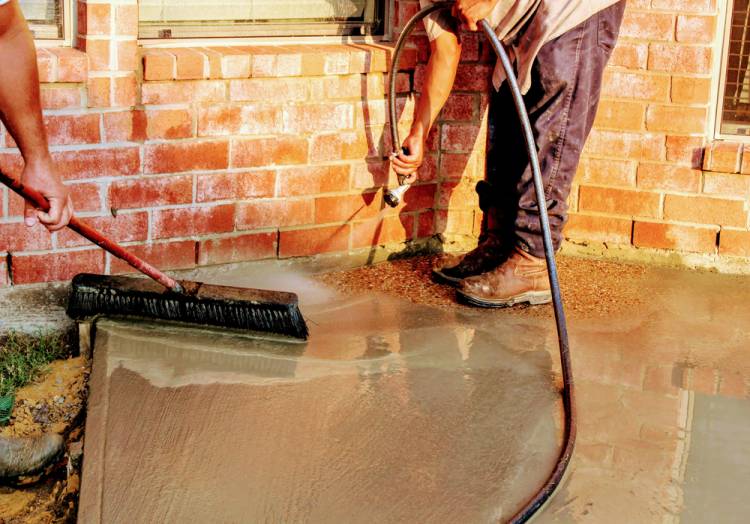

Once the fresh concrete and aggregate elements have been poured, the retarder should be applied when any bleedwater has vanished and you have completed any finishing operations.

The exposed aggregate retarder can be applied using a low-pressure sprayer. At this stage, you need to apply the retarder evenly to ensure the concrete cures at a steady rate. Also, keep an eye on your retarder levels if you’ve chosen one in a bright colour, as this makes it easy to indicate what areas still need to be levelled visually. Don’t worry, the dye will fade after it dries.

Surface retarders work by creating a chemical reaction that slows the rate at which the surface of the concrete sets. While the underlying layers will set at a normal rate, the top surface will stay wet. When it has been set (this can take between 6 and 24 hours, depending on the retarder you are using and the weather), the surface layer can be washed away with clean water from a hose or a high-pressure washer. This will expose the aggregate underneath, which has been safely set in the hardened concrete.

You can test a small area of the retarder to see if it has been set to the level of exposure you want before completely washing it away. If it’s too deep or your aggregate starts coming loose, leave the rest of it to cure for a little longer. But don’t leave it too long – a retarder that has overly hardened will be difficult to remove without damaging the layers underneath your aggregate surface finish.

For a comprehensive guide to the ideal surface for your home, read whether exposed aggregate concrete is the right choice for your driveway!

Tips For Creating The Perfect Finish For Your Exposed Aggregate

A beautiful finish isn’t too hard to achieve if you’ve used a retarder. Here are some tips and tricks to keep in mind so you can enjoy a perfectly exposed aggregate driveway, path or patio.

Sealing For Protection And Longevity

Adding some sort of sealer or varnish over your cured exposed aggregate concrete will help protect the protruding stones from wear and tear. Not only will it stop cars and the weather from wearing down the decorative concrete and stones, but it will also make them easier to clean!

Polishing And Grinding For A Smooth Finish

If you want the look of aggregate concrete without the rough texture, then you’ll want to grind it down flat and polish it. Grinding down the exposed aggregate will create a smoother surface that is more pleasant to walk on, especially in barefoot areas like around the pool that need a non-slip surface.

You can then finish by buffing the flattened aggregate for a polished concrete finish. This is a popular choice for aggregate concrete that is poured indoors, which you’ll often see in large office buildings or warehouses, as it retains its non-slip properties even after buffing.

Clean Your Exposed Aggregate Concrete

Keeping your exposed aggregate concrete clean is easy, allowing your exposed aggregate to always look its best. The stones exposed by the retarder can easily collect dirt and dust, but this is simple to remove with a broom or gentle water spray from a hose.

You can use a high-pressure washer, but keep the pressure reasonable, as powerful jets of water may dislodge or damage the stones. Do you want to learn more? Have a look at how to choose the right exposed aggregate supplies.

No matter how you choose to finish your aggregate concrete, the application of chemical surface retarders to expose the stones is always the preferred choice. Using an exposed aggregate retarder gives you an even finish on your concrete without over-exposing or damaging the stones, setting you up for many years of easy maintenance and enjoyment of your beautiful aggregate surface!

You can discover a range of power tools, equipment, and supplies, including grinders and polishers, at Australian Slate-Crete Supplies.

Trust Australian Slate-Crete Supplies For Quality Exposed Aggregate Retarder

Do you have your heart set on an exposed aggregate concrete surface in your home or business? You can find the perfect retarder at Australian Slate-Crete Supplies!

Whether you’re looking for concrete hardeners, concrete sealers, exposed aggregate supplies, hand tools, stencils, or acid and cleaning chemicals, we are delighted to offer you high-quality exposed aggregate supplies in Melbourne, including retarders for horizontal and vertical surfaces, as well as polishers and grinders for a smooth finish when needed.

Contact us today for more information on exposed aggregate retarders! We’re always keen to chat on 03 9408 7722 and will be happy to help you choose the right retarder and concrete services for your needs.

-

February 4, 2022Sandstone Concrete Stencil

February 4, 2022Sandstone Concrete StencilDo you want to add a touch of luxury and elegance to your concrete projects? If so, then consider using sandstone concrete stencils!

Read More -

February 4, 2022Gloss Brick Sealer

February 4, 2022Gloss Brick SealerGloss brick sealer is a wonderful material for adding a brilliant shine to your brick slip wall feature.

Read More -

February 4, 2022Bluestone Concrete Sealer

February 4, 2022Bluestone Concrete SealerIn a broad sense, the term “bluestone” is sometimes used to refer to a variety of stones. It’s a marketing term rather than a geological one.

Read More